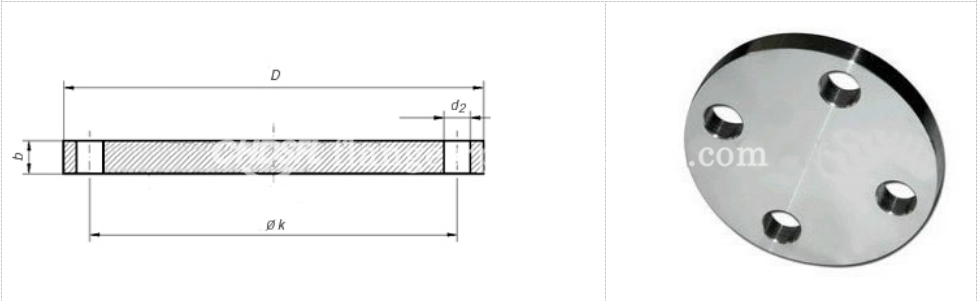

DIN 2527 BLINDFLANGE

PN6, PN10, PN16, PN25, PN40

Flange Dimensiounen & ongeféier Massen

| Däitschland Standard Flange DIN 2527 Blindflens Nominell Drock 6 bis 100 | |||||||

| Blindflansche Nenndruck 6 bis 100 | |||||||

| Brides plaines, nominales pressions 6 à 100 | |||||||

| DIN 2527 PN6 BLINDFLANGE | |||||||

| Bewäert | Flange | Schrauwen | Gewiicht | ||||

| D | b | k | Zuel | Fuedem | d2 | Form B | |

| Kg | |||||||

| 15 | 80 | 12 | 55 | 4 | M 10 | 11 | 0,44 |

| 20 | 90 | 14 | 65 | 0,66 | |||

| 25 | 100 | 14 | 75 | 0,83 | |||

| 32 | 120 | 14 | 90 | M 12 | 14 | 1.18 | |

| 40 | 130 | 14 | 100 | 1.39 | |||

| 50 | 140 | 14 | 110 | 1.63 | |||

| 65 | 160 | 14 | 130 | 2.15 | |||

| 80 | 190 | 16 | 150 | M 16 | 18 | 3.44 | |

| 100 | 210 | 16 | 170 | 4.22 | |||

| 125 | 240 | 18 | 200 | 8 | 6.11 | ||

| 150 | 265 | 18 | 225 | 7,51 | |||

| 200 | 320 | 20 | 280 | 12.31 | |||

| 250 | 375 | 22 | 335 | 12 | 18.54 | ||

| 300 | 440 | 22 | 395 | M 20 | 22 | 25.46 | |

| 350 | 490 | 22 | 445 | 31,77 | |||

| 400 | 540 | 22 | 495 | 16 | 38,49 | ||

| 500 | 645 | 24 | 600 | 20 | 60.10 | ||

| DIN 2527 PN10 BLINDFLANGE | |||||||

| Bewäert | Flange | Schrauwen | Gewiicht | ||||

| D | b | k | Zuel | Fuedem | d2 | Form B | |

| Kg | |||||||

| 15 | 95 | 14 | 65 | 4 | M 12 | 14 | 0,72 |

| 20 | 105 | 16 | 75 | 1, 01 | |||

| 25 | 115 | 16 | 85 | 1,23 | |||

| 32 | 140 | 16 | 100 | M 16 | 18 | 1, 8 | |

| 40 | 150 | 16 | 110 | 2, 09 | |||

| 50 | 165 | 18 | 125 | 2, 88 | |||

| 65 | 185 | 18 | 145 | 3, 66 | |||

| 80 | 200 | 20 | 160 | 4,77 | |||

| 100 | 220 | 20 | 180 | 8 | 5, 65 | ||

| 125 | 250 | 22 | 210 | 8, 42 | |||

| 150 | 285 | 22 | 240 | M 20 | 22 | 10, 4 | |

| 200 | 340 | 24 | 295 | 16, 5 | |||

| 250 | 395 | 26 | 350 | 12 | 24 | ||

| 300 | 445 | 26 | 400 | 30, 9 | |||

| 350 | 505 | 26 | 460 | 16 | 40, 6 | ||

| 400 | 565 | 26 | 515 | M 24 | 26 | 49, 4 | |

| 500 | 670 | 28 | 620 | 20 | 75 | ||

| DIN 2527 PN16 BLINDFLANGE | |||||||

| Bewäert | Flange | Schrauwen | Gewiicht | ||||

| D | b | k | Zuel | Fuedem | d2 | Form B | |

| Kg | |||||||

| 15 | 95 | 14 | 65 | 4 | M 12 | 14 | 0,72 |

| 20 | 105 | 16 | 75 | 1, 01 | |||

| 25 | 115 | 16 | 85 | 1,23 | |||

| 32 | 140 | 16 | 100 | M 16 | 18 | 1, 8 | |

| 40 | 150 | 16 | 110 | 2, 09 | |||

| 50 | 165 | 18 | 125 | 2, 88 | |||

| 65 | 185 | 18 | 145 | 3, 66 | |||

| 80 | 200 | 20 | 160 | 8 | 4,77 | ||

| 100 | 220 | 20 | 180 | 5, 65 | |||

| 125 | 250 | 22 | 210 | 8, 42 | |||

| 150 | 285 | 22 | 240 | M 20 | 22 | 10, 4 | |

| 200 | 340 | 24 | 295 | 12 | 16, 1 | ||

| 250 | 405 | 26 | 355 | M 24 | 26 | 24, 9 | |

| 300 | 460 | 28 | 410 | 35, 1 | |||

| 350 | 520 | 30 | 470 | 16 | 47, 8 | ||

| 400 | 580 | 32 | 525 | M 27 | 30 | 63, 5 | |

| 500 | 715 | 36 | 650 | 20 | M 30 | 33 | 102 |

NOTÉIERT:

1. Fassung nach DIN 2526

Flaach Gesiicht:

Form A, Gesiicht ouni Ufuerderunge

Form B, Face Rz=160, machinéiert (net méi glat wéi 40µm)

Opgehuewe Gesiicht:

Form C, Face Rz=160, machinéiert (net méi glat wéi 40µm)

Form D, Face Rz = 40, machined

Form E, Face Rz = 16, machined

2. Zong a Groove nach DIN 2512

Form F, Zong

Form N, Groove

3. Männlech a Weibchen no DIN 2513, DIN 2514

Form V13, V14, männlech

Form R13, R16, Weiblech

4. Chemfering fir Membran-Schweißverpackungen, PN64-PN400, nach DIN 2695

5. Facing fir Lensfërmeg Gelenker, PN64-PN400, nach DIN 2696

Produktioun Kapazitéit & Kaf Detailer

1. Fourniture Flange Dimensioun DN15 - DN2000 (1/2" - 80"), Forged Flange.

2. Material Kuelestoff: RST37.2, C22.8, S235JR, ST37, P235GH, P245GH, P250GH, ASTM A105

3. Material Edelstol: ASTM A182 F304, F304L, F316, F316L, F321 etc.

4. Flanges Anti Rust: Anti Rust Oil, Black Paint, Yellow Paint Coating, Hot Dipped Galvanized, Cold Galvanized etc.

5. Mount Output: 3000 Tonnen pro Mount.

6. Liwwerung Konditioune: CIF, CFR, FOB, EXW.

7. Bezuelungsbedéngungen: Wire Transfer (T / T), Irrevocable L / C at Sight etc.

8. Minimum Bestellung Quantitéit: 1Ton oder 100Pcs.

9. Qualitéitsgarantie: EN10204 3.1 Zertifikat, Mill Zertifikat, Drëtt Partei Inspektioun, fräi Ersatz Service.

10. Fannt Méi Ufuerderunge An Flanges Maart.